Overview of Our Drum Production Line

At Brit Drum Industries Ltd, our drum production line is a testament to precision engineering. From sheet metal cutting to seam welding, each stage is executed to ensure the highest quality, we transform raw materials into durable drums. We use high tech technology to create strong, leak-proof seams in our drums. Our advanced machines ensure accurate sheet metal cutting, setting the foundation for quality.

Our Experience In Our Product Lines

- Advanced Metal Cutting – High-precision cutting for consistent drum quality

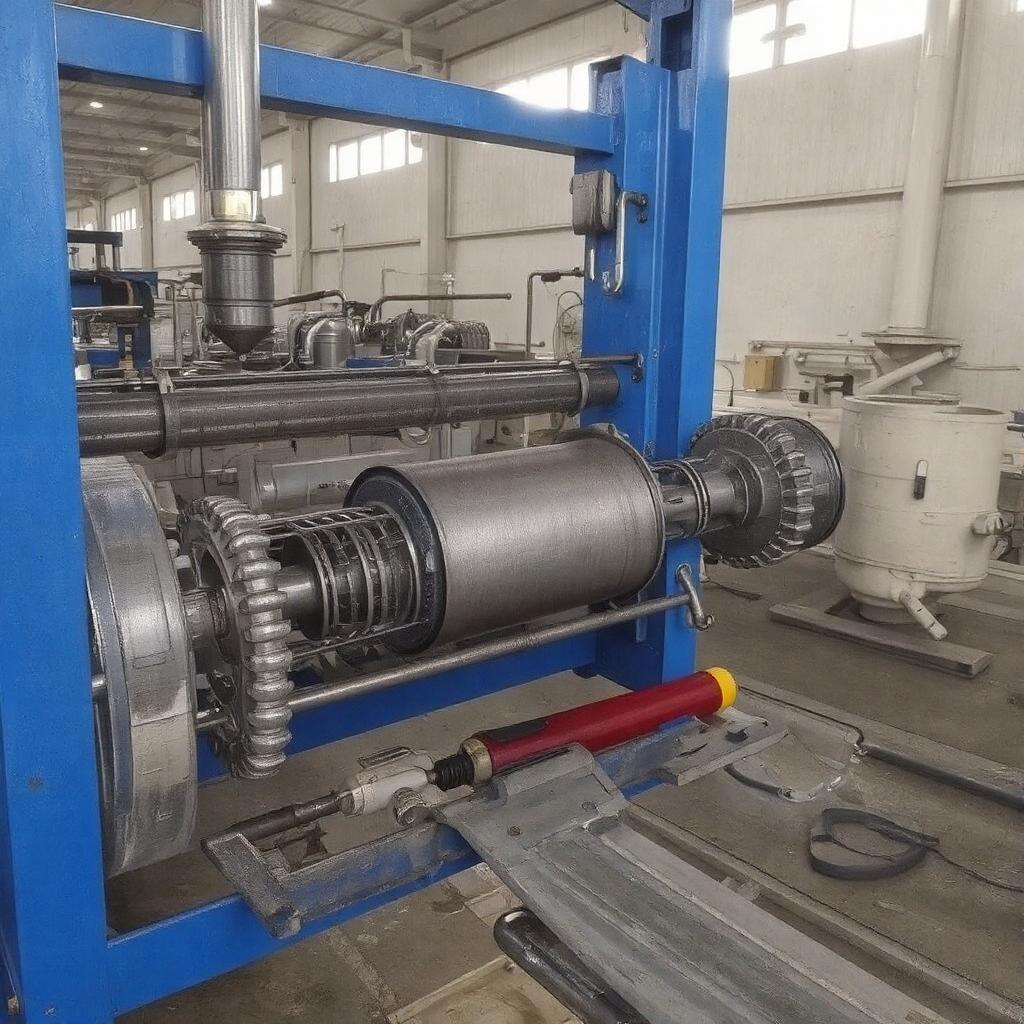

- Efficient Roll Forming – Optimized shaping process for seamless production

- Precision Roll Forming – Ensuring accuracy in drum body formation

- Seam Welding Process – Strong, durable welds for leak-proof performance

- Beading for Strength – Reinforcing drum walls for added durability

- Corrugation for Rigidity – Enhancing structural integrity under load

- Final Drum Body – Ready for industrial applications

Experience Unmatched Precision in Sheet Metal Cutting

Our advanced cutting machines deliver unparalleled precision, ensuring uniform and exact steel sheet dimensions. This detailed process sets the foundation for high-quality drums, guaranteeing consistency and accuracy in every cut.